HOT FIRE TESTING

FULLY MODULAR HOT FIRE TEST STANDS FOR THE FUTURE OF AEROSPACE

14 YEARS

TESTING HYPERGOLIC CHEMICAL THRUSTERS

MULTIPLE TEST STANDS

PRECISION TEST DATA, ACCURACY,

TRANSIENT RESPONSE, AND PROCESSING TIME

SUPPORTING PRIMES

HAS A HERITAGE IN SUPPORTING DEPARTMENT OF DEFENSE, NASA, AND DEFENSE PRIMES

SUNSHINE

The Sunshine test stand was Agile's first stand and has been utilized in the development of 15 different thrusters and combustion devices. Significant upgrades have been made over the years to add capabilities allowing the stand to test a wide variety of engines in all phases of their development. The proprietary method of mass flow measurement enables the verification of pulse mode engine performance.

TEST STAND TYPE

Vacuum hot fire test stand

THRUST RANGE

1–4,500 N (0.25–1,000 lbf)

OPERATIONAL PROPELLANTS

Hydrazine, MMH, MON, M20

PROPELLANT CONDITIONING

Range -50°F to +160°F

ALTITUDE SYSTEM

2-stage ejector or mechanical pump

TOTAL RUN TANK VOLUME

3 gal

MAX RUN TANK PRESSURE

2000 psi

MASS FLOW MEASUREMENT

Positive displacement tank

DACS SYSTEM

Over 400 instrumentation and control channels

DACS System Data rate

Up to 1 MHz

Maximum Nozzle outlet

12”

TEST CELL DIMENSIONS

20” x 20” x 20”

GN2 to LN2 CAPABILITY

Can generate all GN2 needed for testing campaigns from on site LN2 storage.

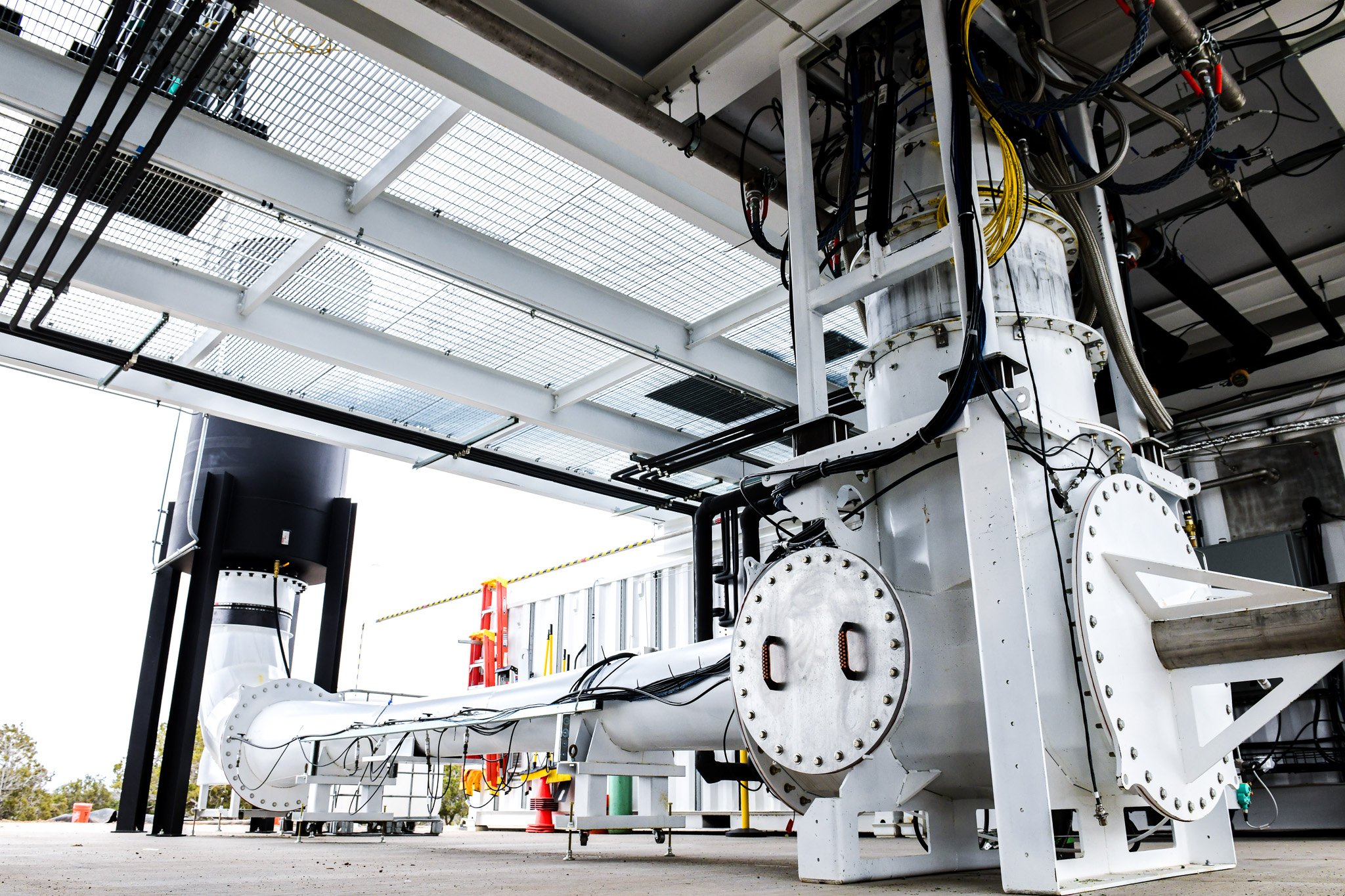

ANIMAS

The Animas Test Stand is Agile's latest and largest test facility. This test stand is designed to accommodate larger engines, longer test durations, and more rapid test campaigns. A modular, spacious design allows for many possible configurations, and multiple runline and run tank sizes in the feed system allow for easy accommodation of many types of combustion devices

ALTITUDE SYSTEM

2-stage ejector

TOTAL RUN TANK VOLUME

130 gal

MAX RUN TANK PRESSURE

2000 psi

MASS FLOW MEASUREMENT

Coriolis flow meter

DACS SYSTEM

Over 500 instrumentation and control channels

DACS System Data rate

Up to 1 MHz

Maximum Nozzle outlet

17"

TEST CELL DIMENSIONS

28"x22"x41"

GN2 to LN2 CAPABILITY

Can generate all GN2 needed for testing campaigns from on site LN2 .storage

TEST STAND TYPE

Vacuum hot fire test stand

THRUST RANGE

Up to 26,700 N (6,000 lbf)

OPERATIONAL PROPELLANTS

Hydrazine, MMH, MON, M20

PROPELLANT CONDITIONING

Range: +45°F to +100°F

MISSION FOCUSED

Rapid and iterative hotfire testing throughout development programs is our key to reducing risk early and delivering on-time. This high cadence testing anchors engine design, validates performance, and ensures reliable products. Agile Space Industries’ hypergolic engine test facilities’ data acquisition systems, propellant conditioning capabilities, and altitude simulation are industry leading.

TESTING HERITAGE

Agile has over a decade of experience testing and qualifying rocket engines and novel combustion devices. We have conducted more than 8,000 hotfire tests on our test stands located at our facility in the Durango, CO. Agile is committed to producing some of the most accurate and reliable test data available in the industry. We test chemical propulsion engines in ambient or simulated environments from 1 - 26,700 Newtons of thrust and are constantly expanding our test facilities to do more.